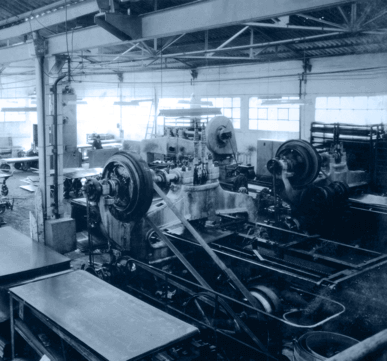

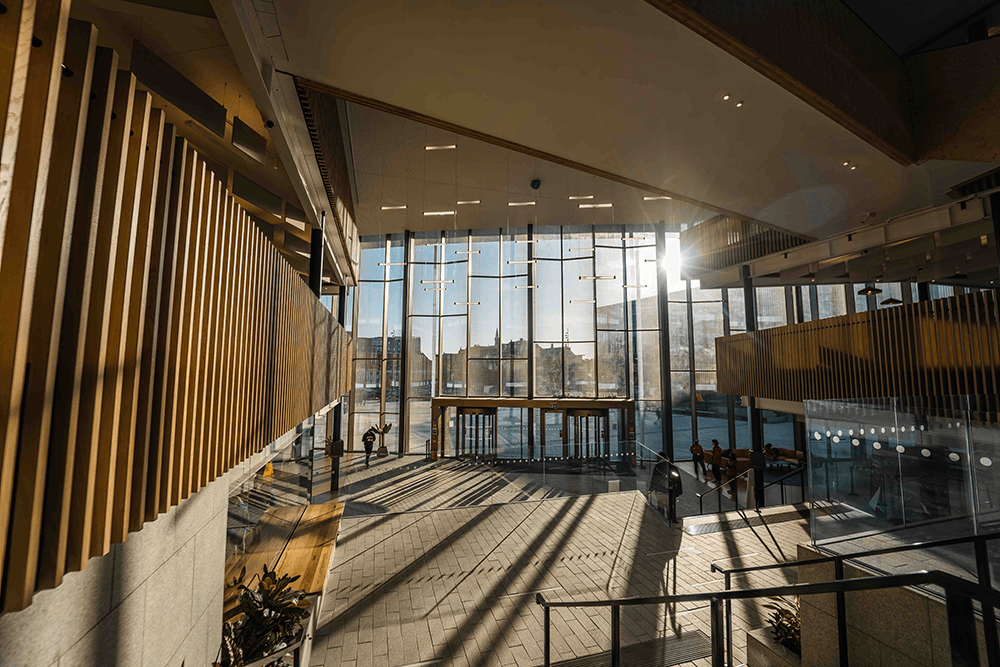

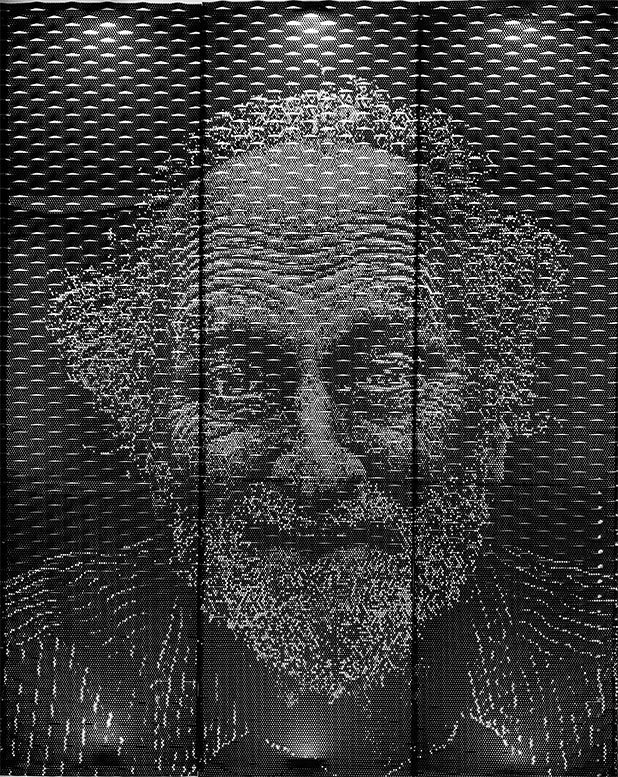

In 1931 we started up in IMAR, the first perforated sheet metal manufacturing machine in Southern Europe. In those years, it was an innovative move. Today, we still think it is. In the engineering and manufacturing of all kinds of solutions in perforated, dimpled, stamped, and expanded sheet metal. Providing solutions to the needs of our clients in two main areas: Industrial and singular architecture.

VALUES

Heritage

Manufacturing metal solutions since 1931.

Know How

Acquired from producing more than 1 million square meters since 2000.

Bespoke Solutions

Making unique applications through a broad range of materials, production processes and finishes.

Comprehensive Service

From engineering and design services to systems and products to be installed.

.png)